Fabric Duct Ventilation

LOW VELOCITY APPLICATION

There are few terms or name uses for fabric ducting ventilation. Sometimes it call as Displacement ventilation, Passive Thermal ventilation and sometimes call as Low velocity ventilation. Fabric ducting first use by engineer for air filtration system which is call as Air-Sox filter because of light weight and space saving especially use for Aerospace industry.

Now fabric ducting widely used for other industry because of huge benefits or advantages compare to conventional steel or rigid duct. From the ASHRAE article September 2004, the Displacement ventilation (DV) cooling uses a low velocity (0.15 to 0.2 m/s [30 to 39 fpm]) stream of more moderately cooled air introduced via diffusers located either in walls at floor level or through a raised floor1. The cooler, slow-moving air slowly spreads over the floor and displaces the warmer, stale air toward the ceiling, where it leaves the room. In spaces with sufficient ceiling height, the air becomes thermally stratified, i.e., warm, stale air is concentrated above the occupied zone and cool, fresher air is concentrated in the occupied zone (up to 6 ft. [1.8 m] above the floor)1.

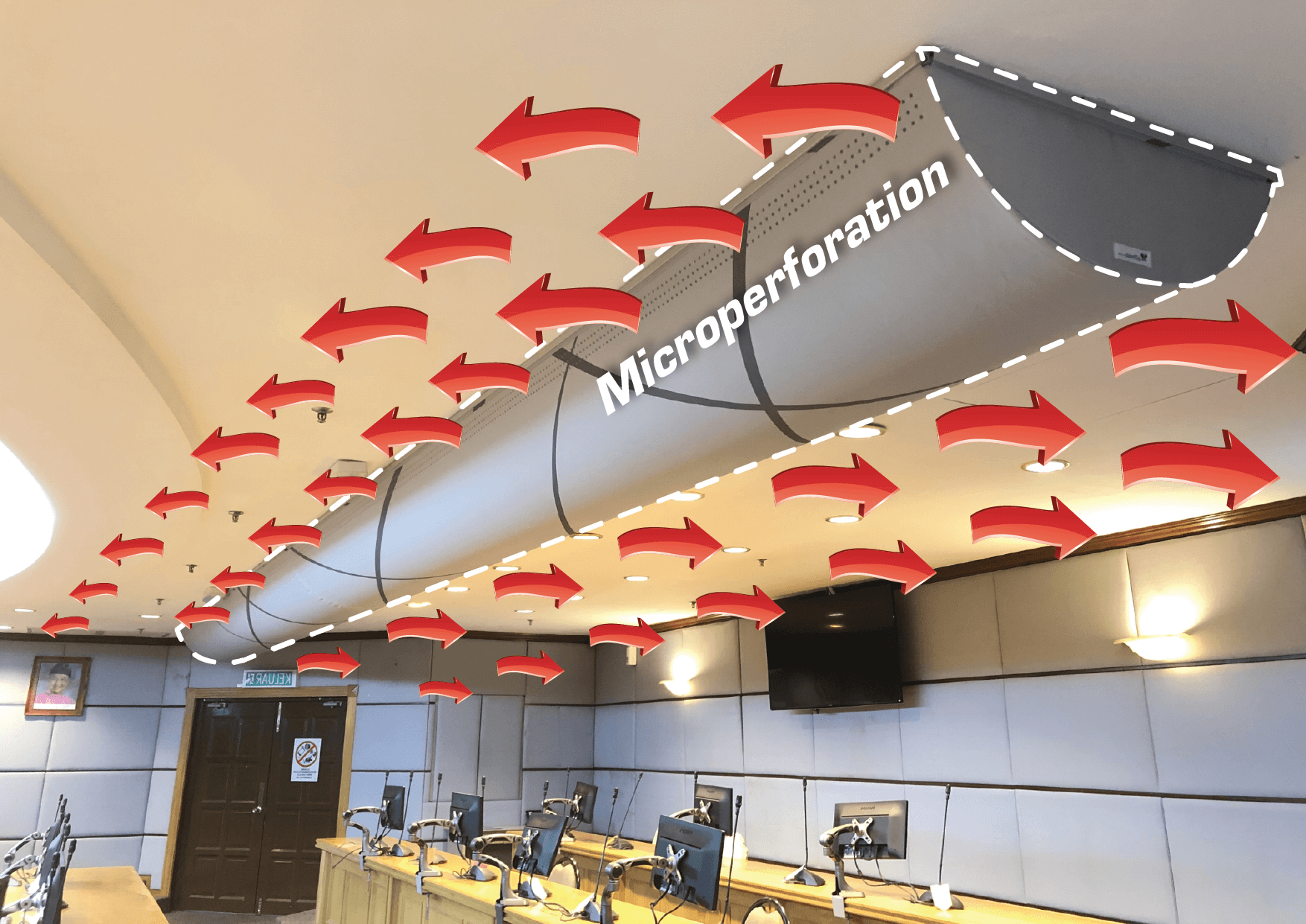

For fabric ducting, the installation can be at the ceiling or at the lower level to follow as what describe in ASHRAE article1. The velocity of air leave the fabric duct as low as 0.1-0.3m/s which means that after few meter from the duct, the velocity become zero. After that the gravitational effect taking place either stay at the high level for heating or moving down to the floor for cooling.

Video at the right show how actual of the cool air flow without any force just after few meter from the duct and the other side is using micro perforation holes for the better displacement ventilation.

Fabric duct with Low Velocity Displacement, slightly depend on the surrounding heat sources. We don’t have fully control on the air movement because it works base on natural process on thermal flow. The cool air is heavier than hot air. The bigger the temperature between supply air and room temperature, the higher the air velocity going down toward the floor.

For the better design of displacement ventilation, the BTU/ft length of the fabric duct is need to be control around 700-1000 BTU/ft length duct to avoid cold draft that can contribute to discomfort room condition.

HIGH VELOCITY APPLICATION

High velocity ventilation / active ventilation / mixing ventilation use where we don’t want the surrounding effect the air displacement. Extreme heat sources will disturb the air displacement pattern and will affect the temperature distribution. To avoid this, mixing ventilation will be the best to maintain the even temperature distribution.

The high velocity air from fabric duct nozzle will create high entrainment of room air. At the high temperature different, the air velocity is high. When arriving the isothermal (Supply air = room temperature) the air velocity decrease.

The high velocity need to design properly outside occupied zone to avoid any discomfort air movement when it enter the occupied zone.

The advantages of using fabric duct vs metal duct, we can really customs control of the air flow distribution to suit the room need/ requirement. We can set the air throw direction, angle & velocity. For example for this badminton hall in uk2.

The challenge is to make sure not blasting air at velocities above 0.15m/s in the courts areas to divert badminton shuttlecocks. The center duct throw the air at the high velocity towards side duct left & right using fabric nozzle and also utilize “Coanda Effect” at the ceiling.

These large Fabric Nozzles can deliver a large volume of supply air but, because they are designed to jet out supply air at high velocity, they also create a lot of mixing and entrainment from the air around these fabric ducts and more generally at high level in the center of the room. This gets supply air and a proportion of room air moving around and flowing in the direction of the wall ducts.

Along the walls we use laser cut perforations sized and cut specifically for each individual project uniquely. The large block of smaller holes deliver air at high exit velocities and allow high levels of entrainment from the surrounding air – which is being blown over by the center ducts. The high entrainment value means that this entrained air needs replacing and this helps draw in the air thrown from the large Fabric Nozzles in the center of the room.

For more details you can read this article at : http://prihoda.co.uk/designing-sports-halls/.

COMBINED VELOCITY APPLICATION

The combination of Low velocity & high velocity gives you more advantage of these two type of ventilation and will enhance comfort. You can create passive or active or passive air displacement. Depend on the room requirement. At last we want to achieve temperature and good air distribution.

The knowledge of how much air going through the permeable fabric and perforation or nozzle must be properly calculated. Prihoda designer use Prihoda own software to design, making the design to be faster and reduce errors.

The static pressure will affect the amount of air going out from the permeable fabric instead of perforation/nozzle. All the air throw from the perforation / nozzle mention in the software will be the distance in isothermal process. So there will be some correction when the supply and room temperature is big different.